Stamping die and tool Description

NEWSKY provide machining services for global customers, Low price, Suitable quality, Rapid response is NEWSKY advantage.

A. Manufacturing capacity:

1) Parts material: Steel, Stainless steel, Aluminum, Mould steel, Carbide etc.;

2) Monthly production capacity: vehicle processing,Mulling processing, Wire-cutting, EDM, Grinding etc.;

3) Certification: ISO9001, SGS;

4) Application areaapplication area: Automobile, electronics, OA, medical treatment, home appliances, daily necessities and so on;

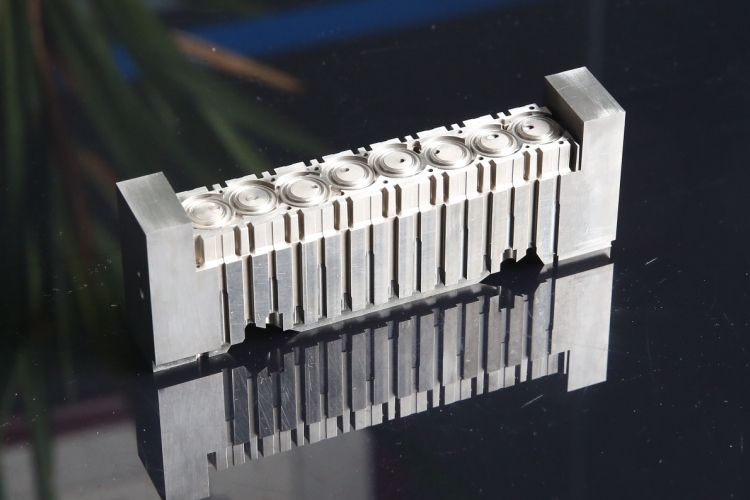

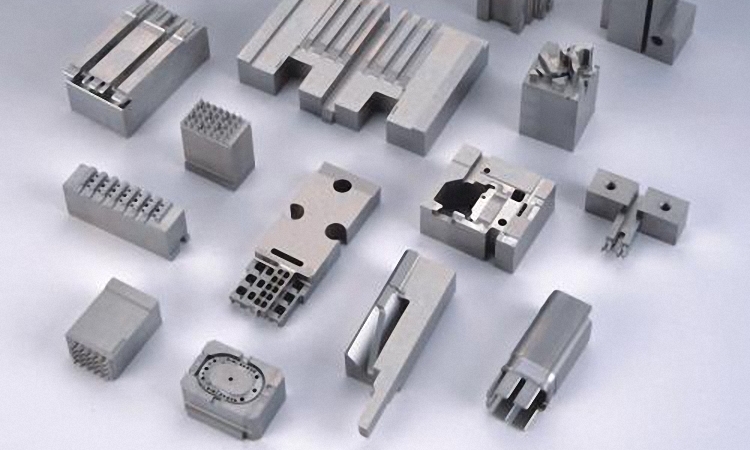

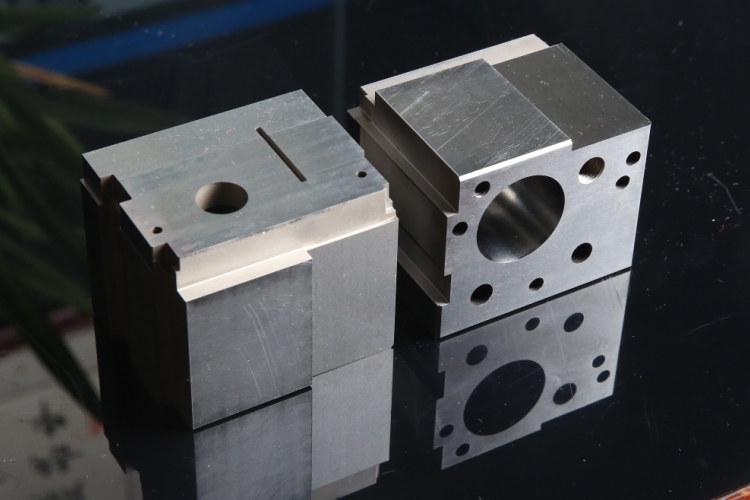

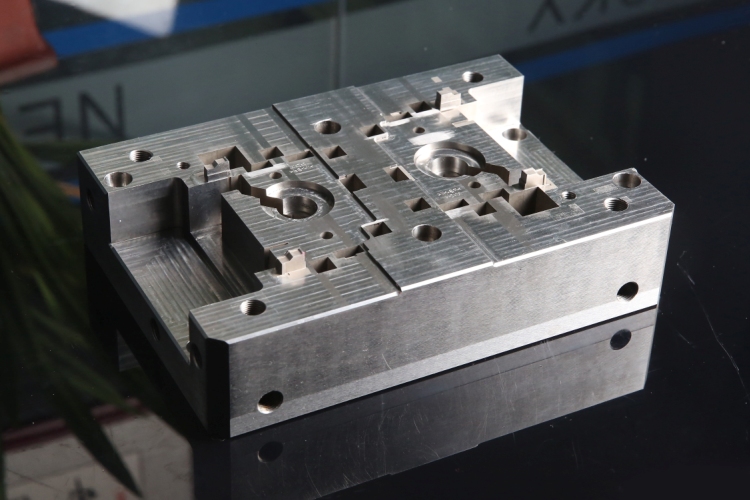

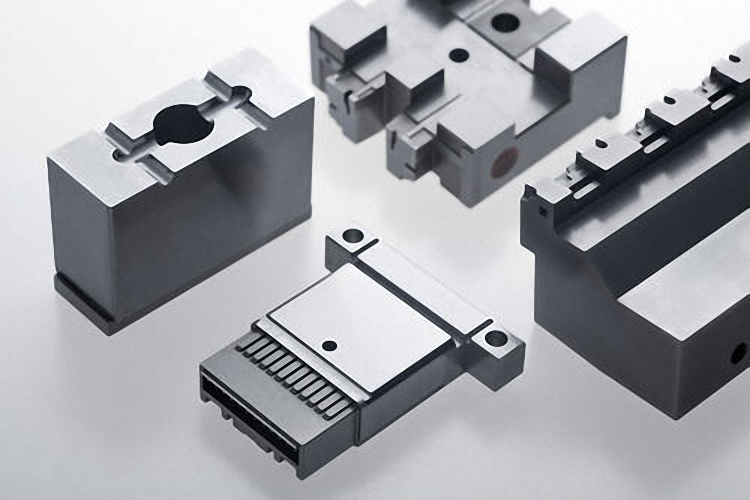

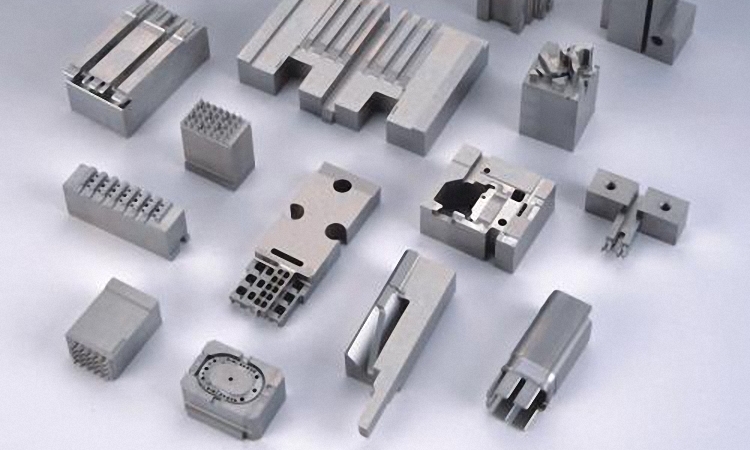

C. Products Show:

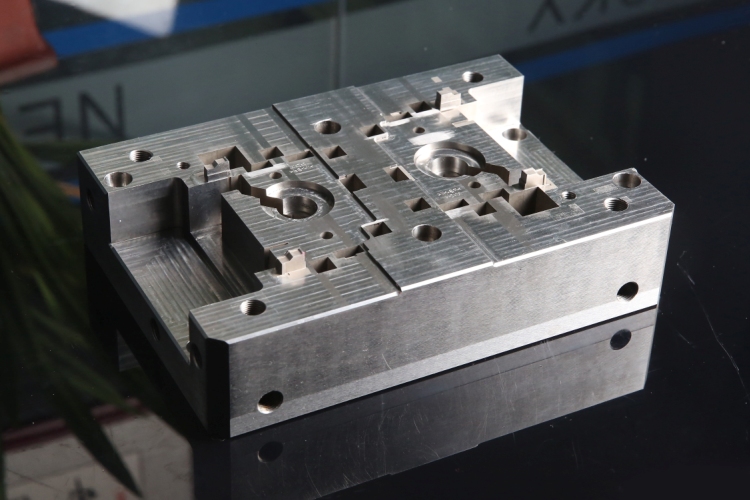

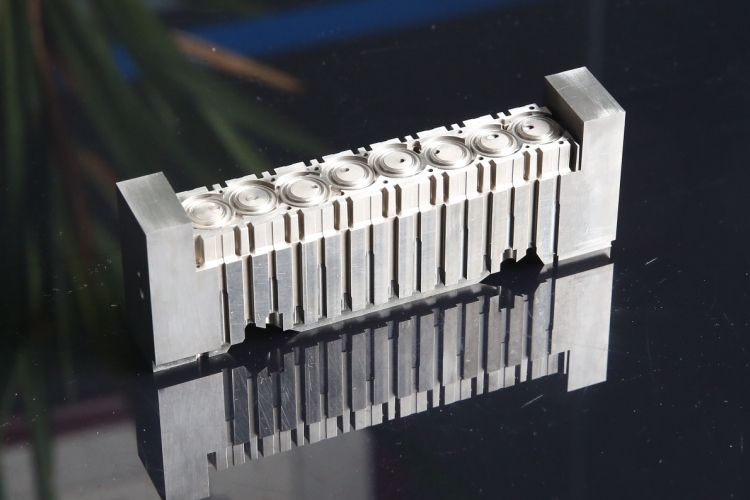

Injection mold core(3D printer than to Milling and EDM)

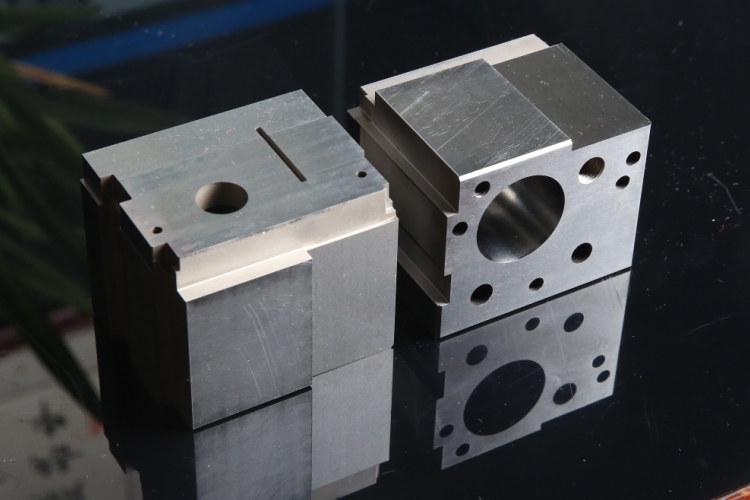

Injection mold cavity

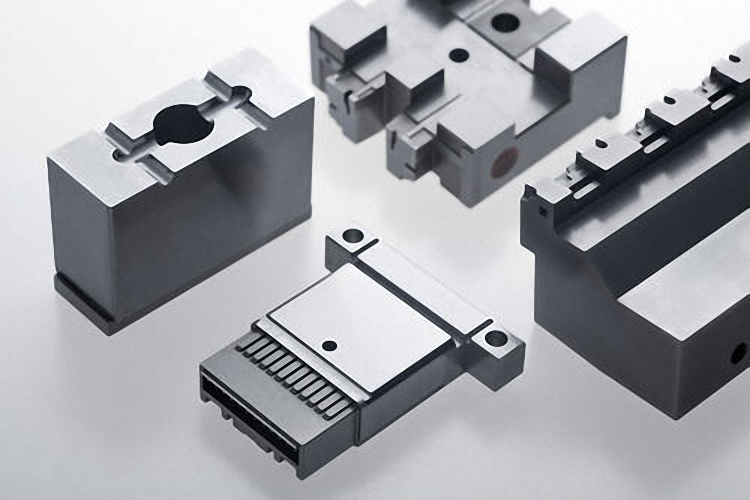

Precision injection mould core

D. Die making machine:

Milling machining

Lathe machine group

CNC Machining

Wire-Cut Machine

Profile grinding machine

F: FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 14 years.

Q: What are your main products?

A: We specialize in manufacturing metal stamping tool ,metal stamping parts.sheet metal parts,cnc machining part and welding structural parts etc.

Q: What is surface treatment do you have?

A: Dacromet ,powder coating,Zinc plated, nickel plated, tin plated, brass plated, silver plated, gold plated, anodizing, salt fog test etc. Due to we are focus on stamping tools and metal stamping parts, surface treatment is done through suppliers.

Q: Can I get the samples?

A: Yes, sample order is available for quality check and market test, and it will be freight collect payment. If simple sample, we will not charge cost; If OEM/ODM samples, we will charge for the sample cost.

Q: What is the MOQ?

A:The MOQ is 1000pcs when have the inventory.

Q:What's the delivery time?

A:The stamping tool manufacturing cycle is 20-50Days, standard stamping parts is 3 to 10 days after paymen. If OEM or make the tooling, we will confirm the delivery time with you.

Q: What's your payment term?

A: we advise 30% T/T deposit, balance be paid before shipment.

Q: Do you received OEM/ODM?

A: YES. We have more than 14years OEM/ODM experience.